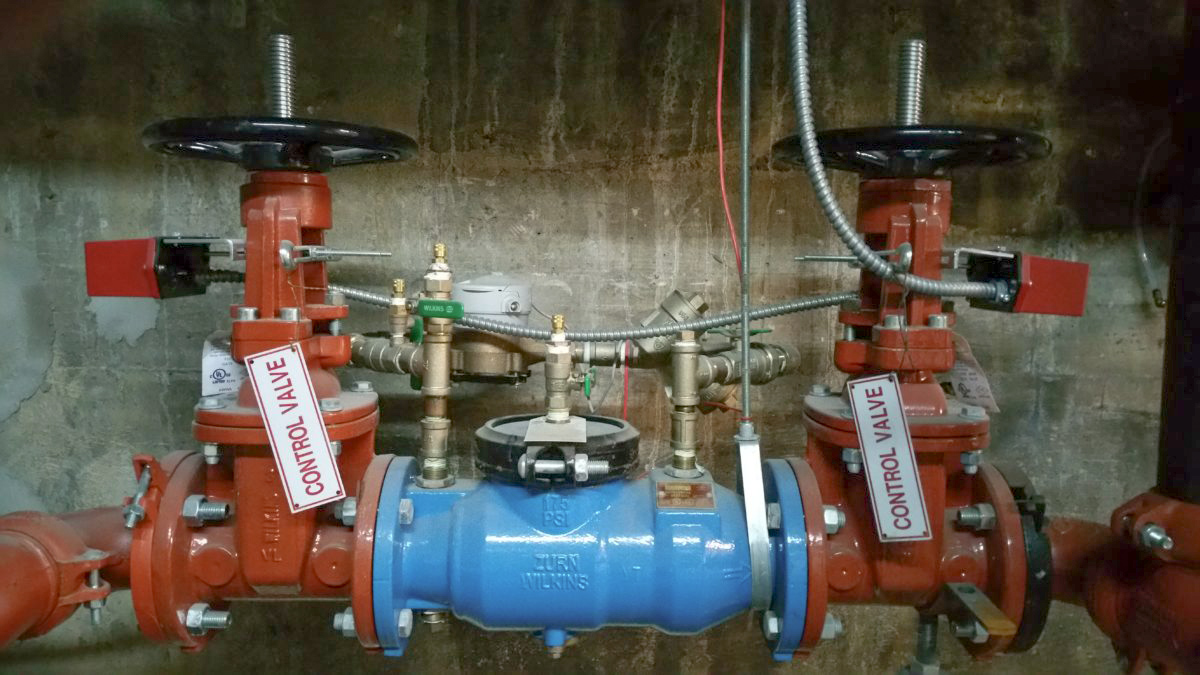

A Backflow prevention device is used to protect potable water supplies from contamination or pollution due to backflow.

In addition to being a leader in the fire protection industry, our team at Chief Fire Protection Company are experts with the installation, testing and maintenance of Backflow prevention systems. Chief Fire Protection Company’s firefighter experience and knowledge allows us to keep your systems running correctly and in compliance with code.

You can count on Chief Fire Protection Company for your Backflow installation, testing and maintenance.

Each jurisdiction may have different requirements that need to be met. Backflow devices are mechanical and have metal, plastic and rubber parts that need to be checked and verified they are in working condition. These parts are under constant water pressure and are susceptible to failure. They will need replacement or repair. On occasion a complete replacement will need to be done in order to uphold the integrity of the water system.

This can be a serious health risk for the contamination of potable water supplies with foul water. In the most obvious case, a toilet flush cistern and its water supply must be isolated from the toilet bowl. For this reason, building codes mandate a series of measures and backflow prevention devices to prevent backflow.

In water distribution systems, water is normally maintained at a significant pressure to enable water to flow from the tap, shower, or other fixture. Water pressure may fail or be reduced when a water main bursts, pipes freeze, or there is unexpectedly high demand on the water system (for example, when several fire hydrants are opened). Reduced pressure in the pipe may allow contaminated water from the soil, from storage, or from other sources to be drawn up into the system.

Chief Fire Protection Company is trusted throughout the southeast and has offices located in Atlanta, Birmingham and Nashville.